CHESAPEAKE

EQUIPMENT EXCHANGE, INC.

CHESAPEAKE

EQUIPMENT EXCHANGE, INC.

Phone:

410-675-8205 Fax: 410-675-3761 Email: gizzmo@erols.com

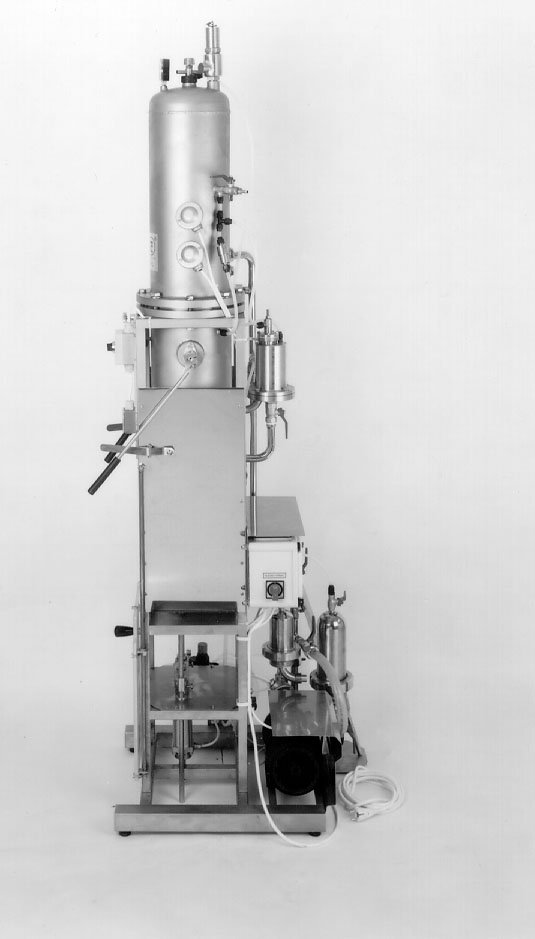

MODELCW

250 CARBONATING

AND COUNTER PRESSURE BOTTLE FILLING EQUIPMENT;

MODELCW

250 CARBONATING

AND COUNTER PRESSURE BOTTLE FILLING EQUIPMENT;

This two valve carbonating and bottle filling

machine has been designed to meet the demand for small scale production

of carbonated products and packaging into a wide

range of containers.

Capable of filling a wide range of products into glass or P.E.T. bottles of sizes ranging from 0.2 liter to 2 liters.

Simple to change bottle size and can also fill cans for pilot line / Research & Development uses. Counter pressure filler carbonator can be bypassed for filling non-carbonated products under pressure.

Features include;

![]() WIDE RANGE

OF BOTTLE SIZES FROM 0.2 LITER TO 2 LITER CAPACITY

WIDE RANGE

OF BOTTLE SIZES FROM 0.2 LITER TO 2 LITER CAPACITY

![]() SIMPLE

TO OPERATE AND FLEXIBLE

SIMPLE

TO OPERATE AND FLEXIBLE

![]() CAPABLE

OF CARBONATING AT AMBIENT TEMPERATURES

CAPABLE

OF CARBONATING AT AMBIENT TEMPERATURES

![]() FILLING

OF GLASS BOTTLES AND P.E.T. BOTTLES, OR CANS

FILLING

OF GLASS BOTTLES AND P.E.T. BOTTLES, OR CANS

![]() AVAILABLE

WITH ADDITIONAL CHILLING IF REQUIRED

AVAILABLE

WITH ADDITIONAL CHILLING IF REQUIRED

![]() FILLING

STILL OR CARBONATED PRODUCT

FILLING

STILL OR CARBONATED PRODUCT

![]() CARBONATING

PRODUCT PRIOR TO FILLING

CARBONATING

PRODUCT PRIOR TO FILLING

![]() INTEGRAL

PRODUCT PUMP

INTEGRAL

PRODUCT PUMP

![]() COMPACT

COMPACT

![]() SIMPLE

TO CHANGE BOTTLE SIZES

SIMPLE

TO CHANGE BOTTLE SIZES

![]() SUITABLE

FOR A WIDE RANGE OF BEVERAGES INCLUDING BEER, WINE, SOFT DRINKS, MINERAL

WATER, CIDER AND CHAMPAGNE

SUITABLE

FOR A WIDE RANGE OF BEVERAGES INCLUDING BEER, WINE, SOFT DRINKS, MINERAL

WATER, CIDER AND CHAMPAGNE

![]() ALL STAINLESS

STEEL CONSTRUCTION

ALL STAINLESS

STEEL CONSTRUCTION

Technical Specification

CW 250

Maximum capacity of carbonated

beverage .........................................................................

250 ltrs/hr Maximum C02 content in beverage..........................................................................................

13 g/ltr Maximum carbonation overpressure ......................................................................................

800 kPa Number of filling valves.............................................................................................................

2 pcs

Inlet temperature of beverage ...............................................................................................

17 deg.C Outlet temperature of beverage ...........................................................................................

5-7 deg.C Adjustable height of bottle ..............................................................................................

180-320 mm

Capacity of bottles ..............................................................................................................

0.2-2.0 ltr Maximum C02 consumption ...................................................................................................

4 kg/hr Cooling Agent ............................................................................................................................

R 22 Power demand ......................................................................................................................

0.8 kWh Feeding ..................................................................................................................................

3 x 380 Weight .......................................................................................................................

approx. 120 kg Dimensions ...............................................................................................................

0.5 x 0.5 x 2.1m

Mean number of filled bottles 0.75

ltr per one 20kgs CO2 pressure bottle................. approx. 1400 pcs